Our Research area

In the frame of a continuous improvement in the measurement techniques for turbomachinery applications, the LFM group is devoting efforts on probes development for both staedy and unsteady measurements.

On probes for STAEDY MEASUREMENTS the main isssues concern miniaturisation, accuracy and customisation for specific applications. In this field, pneumatic 5hole and 3holes probes are continuosly improved.

On probes for UNSTAEDY MEASUREMENTS the main isssue concerns the tradeoff between miniaturisation and prompness, being awared of accuracy, customisation and reliability. A number of Fast Response Aerodynamic Probes – characterised by a cylindrical head, 1 hole and operated as virtual 3 hole probes – have been designed, manufactured and proficienlty tested up to a frequency response of 100 kHz, in the temperature range 0-270 °C and up to transonic conditions.

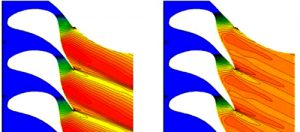

The research on linear cascades in Blow down Wind Tunnel, is generally addressed to the evaluation of the influence of several different operational conditions (Mach number, incidence angle, stagger angle, cascade solidity, etc.) on the downstream secondary flow field and on the aerodynamic performances of the profiles. Moreover, data allows to evaluate the influence of the cited parameters on the radial discharge angle distribution produced by secondary flows. A typical result is reported in figure 2 in terms of kinetic energy loss contours and secondary velocities vectors distribution.

Current turbomachinery architectures result in reduced stator-rotor axial gaps, amplifying the unsteady coupling between the stationary and rotating components. In this context, a number of research programs were carried out and are currently ongoing at LFM about the blade row interaction in turbomachinery. In particular, the stator-rotor interaction in high pressure turbines and the impeller-diffuser coupling in centrifugal compressors have been studied; the research programs have been performed in both the closed-loop, high speed/low speed test rigs of LFM.

The flexibility of the test high speed rig of the Politecnico di Milano has allowed to carry out a wide parametric study of the stator-rotor interaction in a high pressure turbine. In general, the interaction promoted by stator vortices with the rotor flow field represents the key-feature in these stages.

Nowadays Organic Rankine Cycles (ORCs) represent a viable technology for conversion to electricity or to combined electricity and heat of energy coming from low/medium temperature sources. These are often clean sources such as renewables and heat recovery. Typical applications are found in low/medium-power electrical generation, especially in Combined Heat and Power (CHP) configuration, and for installations in remote or harsh environments.

Aerodynamics performances and operating characteristics of Wind Turbine:

-

Generators in the Large scale Wind Tunnel facility of Bovisa (In collaboration with University of Trento – Prof. Battisti)

-

Downstream phase resolved flow field (wakes) for the characterization of wind farms