High Speed Closed Loop Test Rig

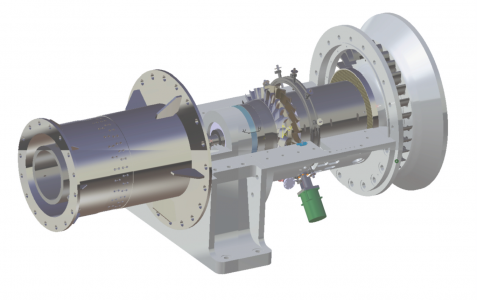

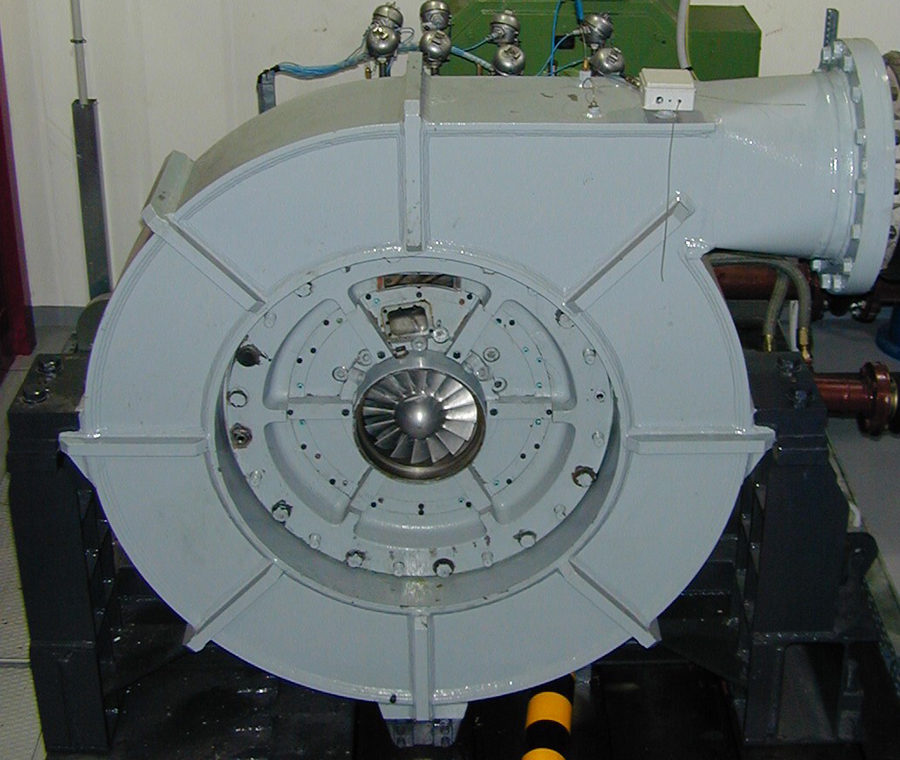

Axial And Radial Stages

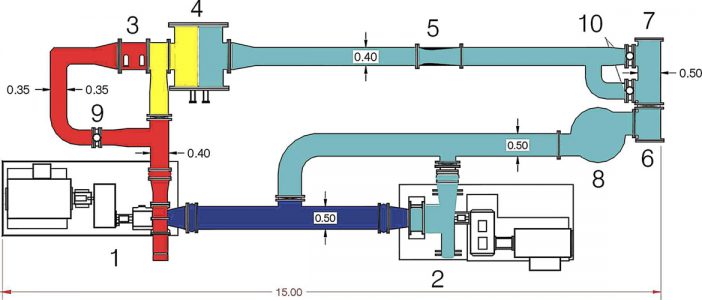

For the aim of research programs on axial turbines and centrifugal compressors a closed loop test rig for axial and centrifugal turbomachines has been launched in 2001 at LFM.

The test rig is equipped with:

-

-

-

section for centrifugal turbomachines

-

cooling section

-

Venturi nozzle for the flow rate measurement

-

filtering section

-

flow rate can be exhausted either in the by pass line or in the axial section

-

-