Blow Down Linear Cascade

Transonic and supersonic blow-down wind tunnel for linear cascades

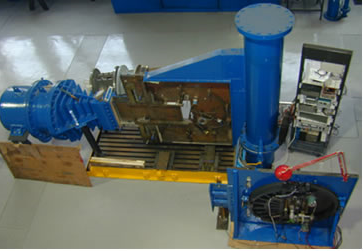

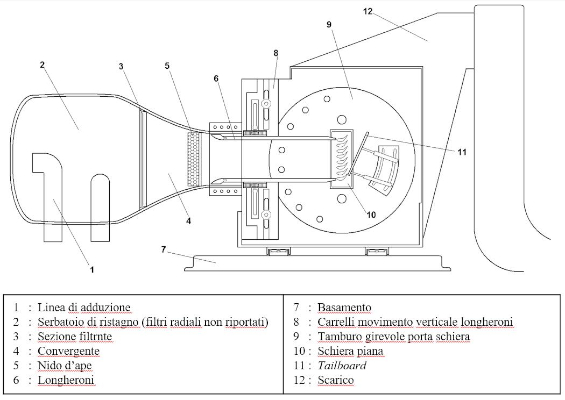

Test facility consists of a transonic and supersonic blow down wind tunnel for linear cascades. The test section, 400 mm wide in tangential direction, allows to install linear cascades with a relatively large number of blades, providing a high quality of flow periodicity. Cascades characterized by 50 mm or 80 mm height can be tested. The facility is supplied by means of an air storage of 6000 kg at 200 bar, allowing long testing time also in supersonic conditions. Maximum available flow rate is 7 kg/s. A secondary flow rate supply system is provided in order to perform aerodynamic measurements on film cooled blades.

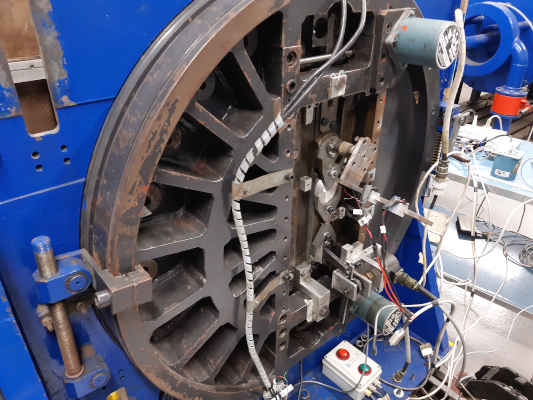

The wind tunnel is equipped with a fully automated and computer controlled data acquisition and 3D traversing system, both upstream and downstream the cascade. Up to 100 pressure signals can be acquired during tests in order to define static pressure distribution on blade and endwall surfaces.

Typical measurement are performed with pneumatic directional probes (5 hole probes) and hot wires. Optical measurement are allowed by the installation of glass window in the test section: LDV and Schlieren can be easily performed. In particular, Schlieren technique is applied run-time when performing supersonic tests in order to check flow periodicity and shock patterns.