Low speed closed loop test rig for turbine axial stages

Large scale - High accuracy - Easy and Economical

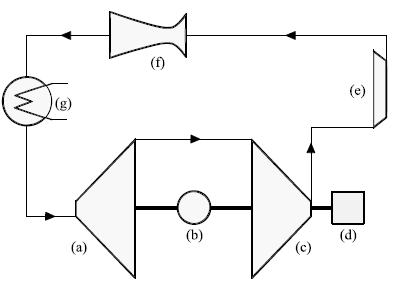

Test facility consists of a subsonic-transonic closed loop wind tunnel for turbine stages.

The flow rate is provided by a variable rotational speed centrifugal blower equipped with IGV, allowing a maximum capacity of 15 m3/s.

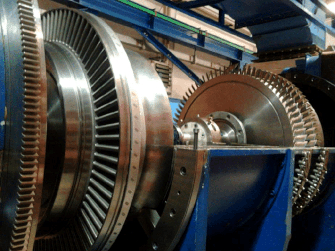

The test section can house up to two full turbine stages with a maximum blade height of 200 mm and a maximum tip radius of 890 mm.

The turbine is bracken by a two stage axial compressor equipped with IGV and variables stator vanes in order to increase the operational range. Compressor and turbine are installed on different shafts, connected through a high accuracy torque-meter. The maximum rotational speed is 3500 rpm; the fine setting of the rotational speed is guaranteed by an electrical brake (maximum 80 kW) operating on the compressor shaft. The extra compression ratio provided by the axial compressor allows a maximum expansion ratio of 2.1 on the turbine section.

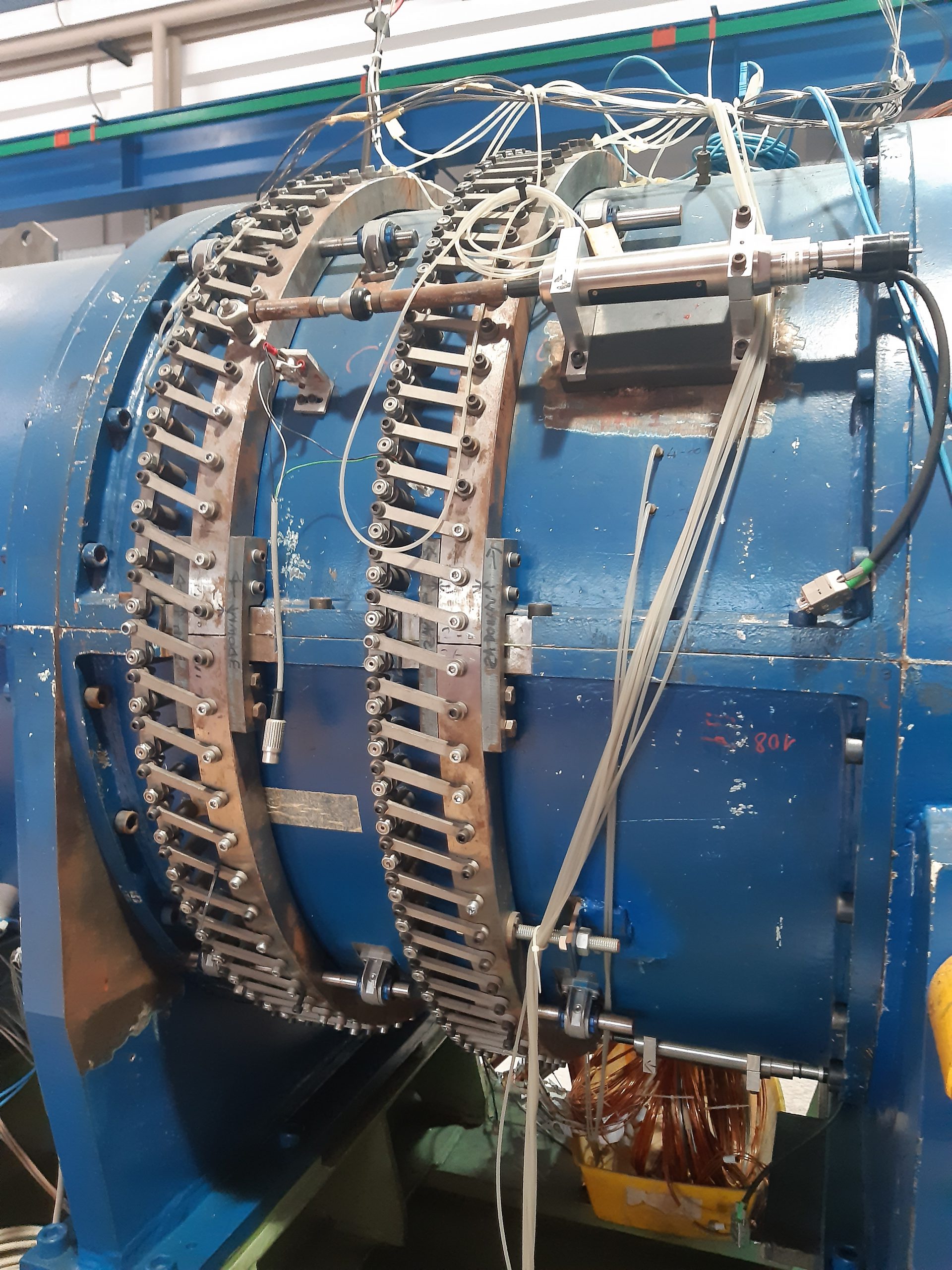

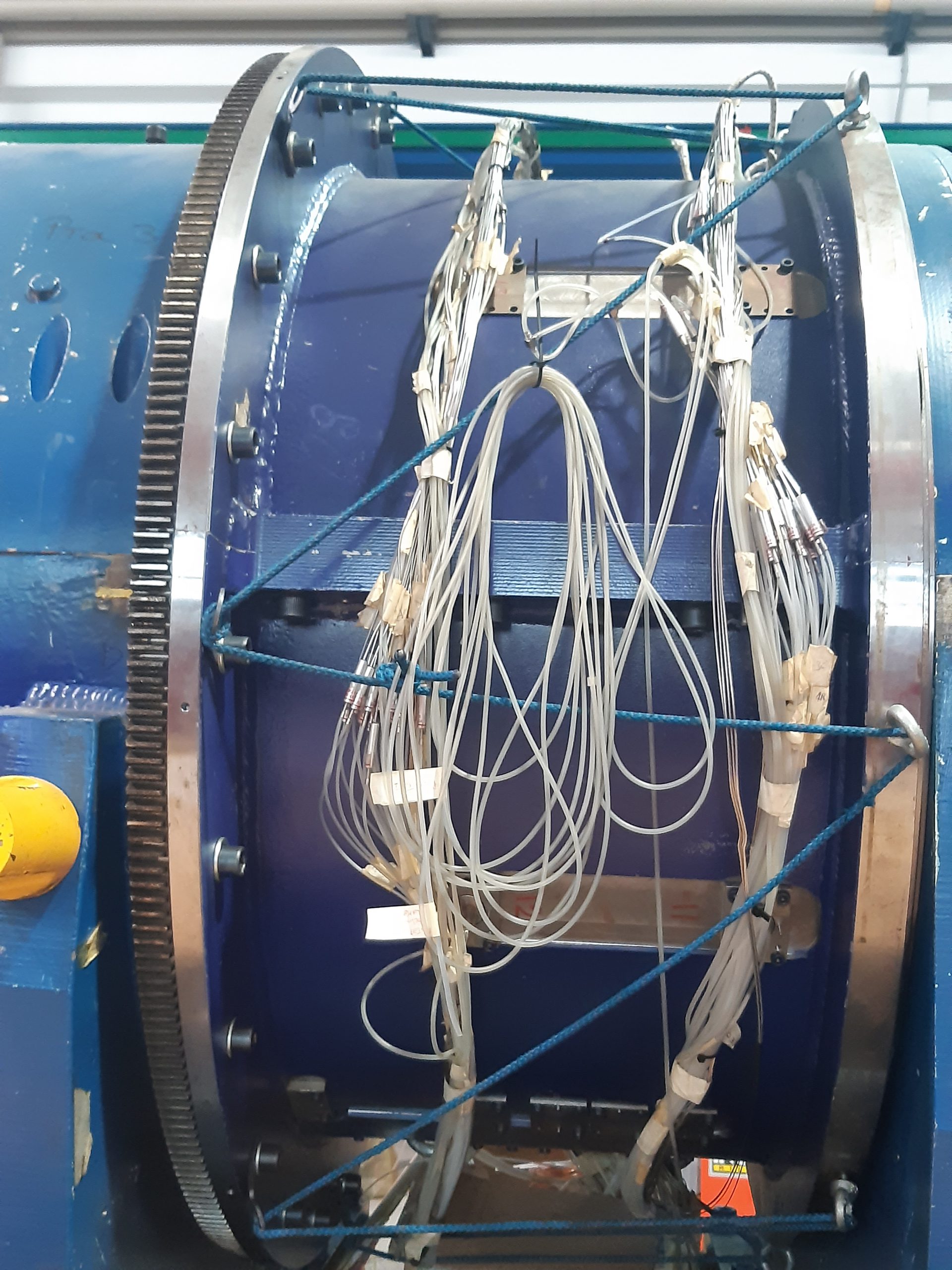

The wind tunnel is equipped with fully automated and computer controlled data acquisition and 3D traversing system for detailed flow field measurements.

The facility has been mainly designed for detailed steady and unsteady aerodynamic measurements, but overall performance evaluation can be easily performed.

Classic Venturi tube, designed according to ISO 6157.

The large diameter of the pipes (800 mm) and the high fidelity required on the measurement of the mass flow, the venturi has been calibrated with the use of a nozzle in sonic conditions (as indicated in ISO 5167). The result is an uncertainty of up to 0.5% of the measured value.

- Turbine Stage

- Torque Sensor

- Axial Compressor: 2 stages + IGV and VGVs

- DC Motor: 80 kW, 3000 rpm

- Centrifugal Blower: 500 kW, 20m3/s, βfan=1.2, variable speed;

- Venturi Nozzle

- Heat Exchanger